How to build a Hi-Fi power cable? New Ricable video guide

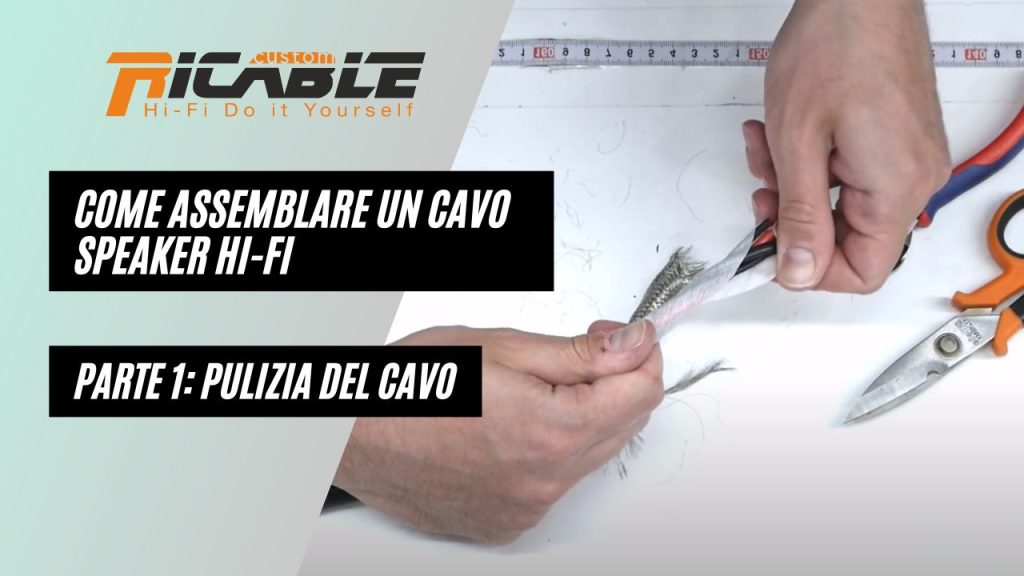

How to build a Hi-Fi power cable? After the tutorials on how to build a cable Speaker e a signal one, here we come to show you how to assemble a Hi-Fi power cable entirely on your own. With this latest video tutorial, divided into two parts and available on the Ricable YouTube channel, we thus cover the request of the majority of DIYers and audiophiles, that is, those who, at least in structure, have a "simple" system, thus consisting of source, amplifier and speakers.

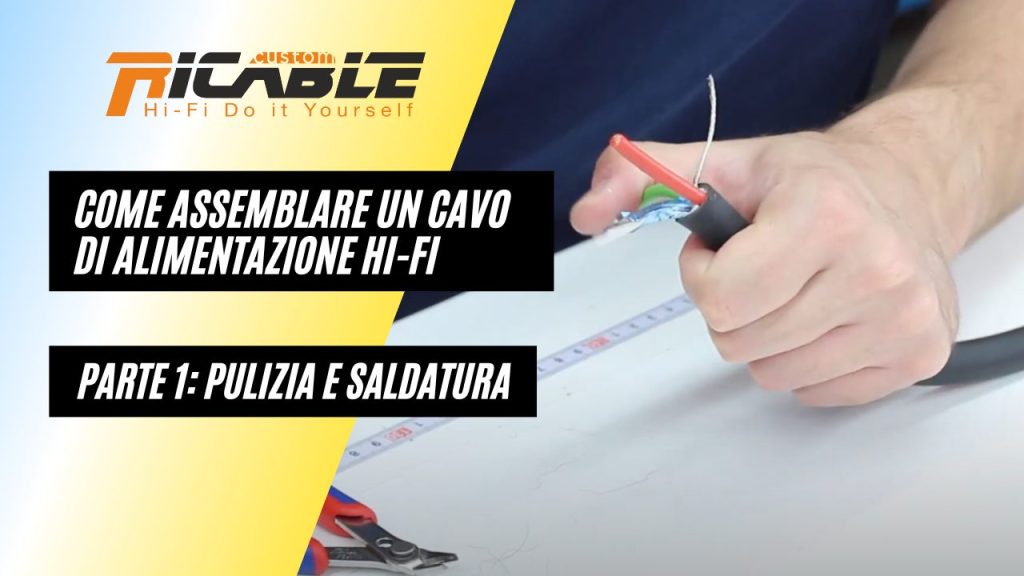

Cleaning and welding

The first video on how to build a Hi-Fi power cable focuses on cleaning and soldering the cable. We remove a piece of sheathing and peel off the braid. We now remove the cotton cord insulation and the aluminum foil covering the conductors. We can now strip the conductors, cutting the dielectric. We wrap the red and white conductors onto themselves, while the green conductor we wrap together with the ground wire. Thanks to this configuration, the captured interference will flow into the grounding of the electrical system. Now we can move on to soldering the conductors. Finally, we cut a piece of heat shrink tubing to the size of the conductor and heat it on the green wire.

Connections

The second part of the guide focuses on connections. First, we also clean the cable at the other end; here we will apply the IEC connector. At the side with the ground joined to the shield we will install the Schuko socket. We unscrew the shell and remove the rubber gasket. After other preliminary operations, our connector is ready. For convenience we run the shell through the cable and later strip the conductors. Now we install the IEC socket following the directions: line, neutral and ground. We bring the shell to the connector and tighten all the screws. On the other side we install the Schuko, paying attention to each conductor. We finally tighten the shell with all the screws.

Here is our power cord

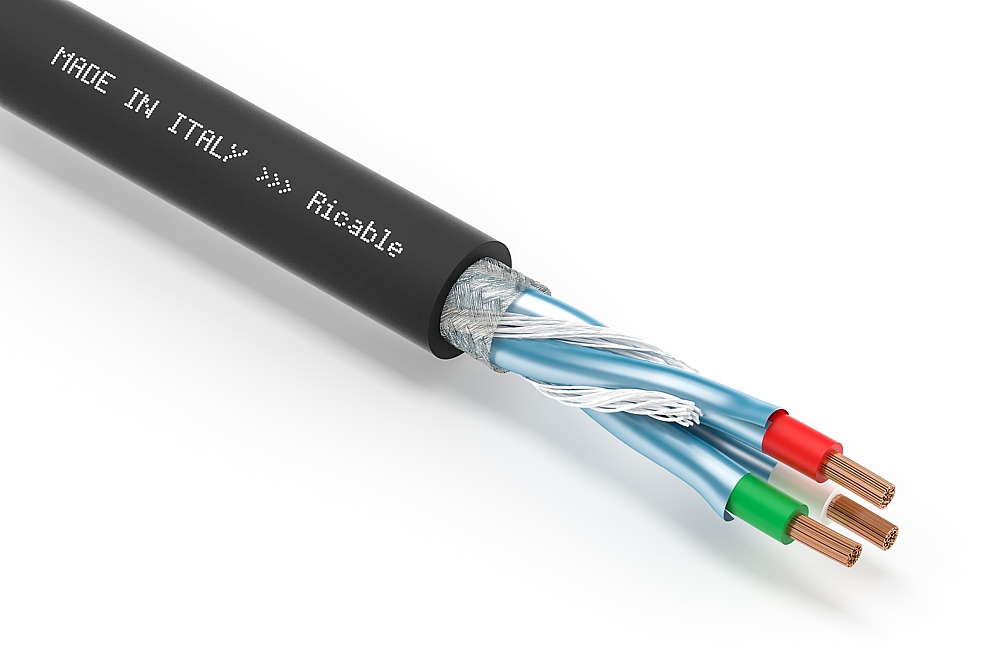

After having made a Speaker cable and a signal cable, today we have completed our very personal "trilogy" with the power cable. Be sure to click on the button below, thanks to which you will be immediately catapulted to the Ricable YouTube channel. By selecting the button further down, however, you can take a quick look at the entire catalog Ricable Custom.